Congenital heart disease (CHD) is a physical heart defect that begins in the womb, impacting around 40,000 children born in the U.S. each year. On a mission to improve education for diagnosed children and their families, Drs. Amr El-Bokl and Gurumurthy Hiremath (Department of Pediatrics, UMN Medical School), partnered with product design undergraduate student Levi Skelton and Assistant Professor Carlye Lauff to create a product for teaching children about CHD.

Varying from mild to severe cases, CHD can manifest in several different ways, from valve complications to an upside-down heart. These variations make the condition especially difficult for children and their parents to understand and manage, particularly as CHD patients age and become more independent.

“There is a tendency to try and protect children from information,” explained Dr. El-Bokl. “This continues as they grow, then all of a sudden they’re leaving for college or starting their first job and have only a vague idea of their heart condition. Slow and early introduction is one of the best ways to become familiar with the medical information, but we don’t have many child-friendly tools to facilitate this.” To help close that gap, Dr. El-Bokl and Skelton embarked on the design process journey to create a better educational tool for children and their parents.

With no prior experience working with medical professionals or knowledge of CHD, Skelton dove headfirst into the project. “I started by researching CHD, how it can manifest, be managed, and sometimes corrected. It was a deep dive into a niche part of the medical field, and I really enjoyed learning about it. I had done some previous interdisciplinary work, but this was very different because Dr. El-Bokl was my client and mentor. While he taught me about CHD, he was also telling me what he wanted out of the product,” reflected Skelton.

Part of the learning and design process included an immersive, two-day experience volunteering at Camp Odayin, a residential summer camp for children with heart disease. “My favorite part and also the part that taught me the most was seeing that these kids really aren't much different from any others. I had been researching CHD for a month at that point and I had seen some kids in the clinic, but after being told the heart conditions these kids had and knowing exactly what that meant, it was really cool to see them running around and having fun like any other kid,” explained Skelton.

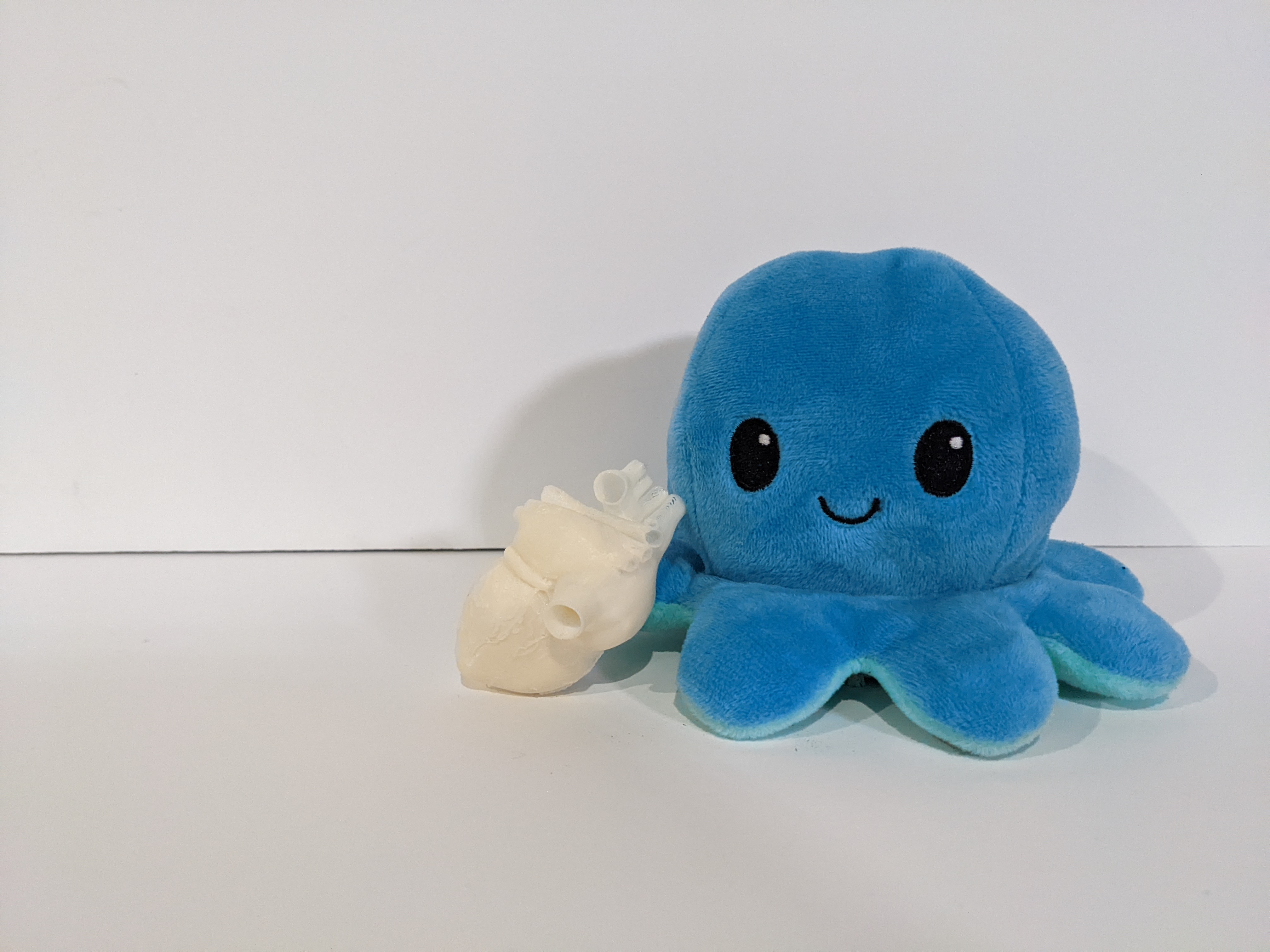

After conducting his research and speaking with a child life specialist, Skelton decided that an animal companion toy would be the most effective way to meet his project goals. “Having children simulate a doctor/patient interaction with themselves and a toy has been proven to help children feel more comfortable as a patient during a visit to the doctor,” said Skelton. “Once I decided on creating a toy, I researched animals with unique hearts and chose the octopus because it has three of them!” The plush octopus, or Octo, is designed with a removable, 3D-printed heart and features a digital app for kids to administer checkups and learn about cardiovascular functions.

Reflecting on the final prototype and its potential, Skelton sees a bright future for the continued collaboration between the medical and design fields. “I think designers have a lot to bring to the medical field, especially for children. I think as UX design gets more popular, it will contribute the most to hospitals because the user experience is a top priority,” said Skelton.

Funding for this project came from a grant by The Lasting Imprint, a non-profit corporation established by individuals committed to fighting congenital heart defects.

Innovation starts with new challenges and fresh perspectives, a concept well known to both the Product Design program and Andersen Corporation. This notion formed the basis of their spring 2021 collaboration when graduating product design seniors worked directly with Andersen Windows and Doors products and professionals to develop solutions for “bringing the outdoors in” as part of their capstone projects.

Driven by the acute need for N95 masks in hospitals, faculty from the University of Minnesota’s College of Design, College of Science of Engineering, and medical school worked together to create two face mask designs that could be assembled using available materials.

The scarcity of N95 masks has occupied headlines and the minds of the public since the outbreak of COVID-19—hoarders of the masks have been busted, stockpiles have been donated, and several alternatives have been developed.