You can’t break something that is already broken. Understanding this piece of wisdom is the first step in the process of repair and part of the foundation for a new freshman seminar in the College of Design, DES 1408: Dare to Repair.

The new class centers on the idea that climate solutions can be joyful and teaches students from across the University of Minnesota to embrace the power of repair as a personal tool, means to foster community, and agent for positive change. Led by Fabrication Director Molly Sanford and Apparel Design Lecturer Lindsey Strange, DES 1408: Dare to Repair offered students a chance to learn about the concept of repair, product life cycles, consumerism, waste management and sustainability, and community engagement through a variety of hands-on projects and field trips.

“As a college, we have a tremendous opportunity to shape the next generation of designers. We need to help students develop the tools to imagine radical, new possibilities for our struggling world. Hands-on repair is an option that reconnects us with our belongings and empowers us on an individual scale to interrupt unhealthy patterns of consumerism,” explained Sanford.

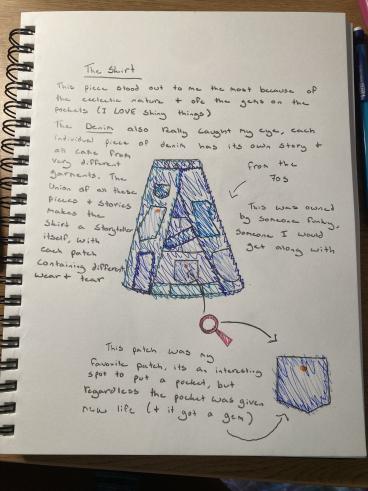

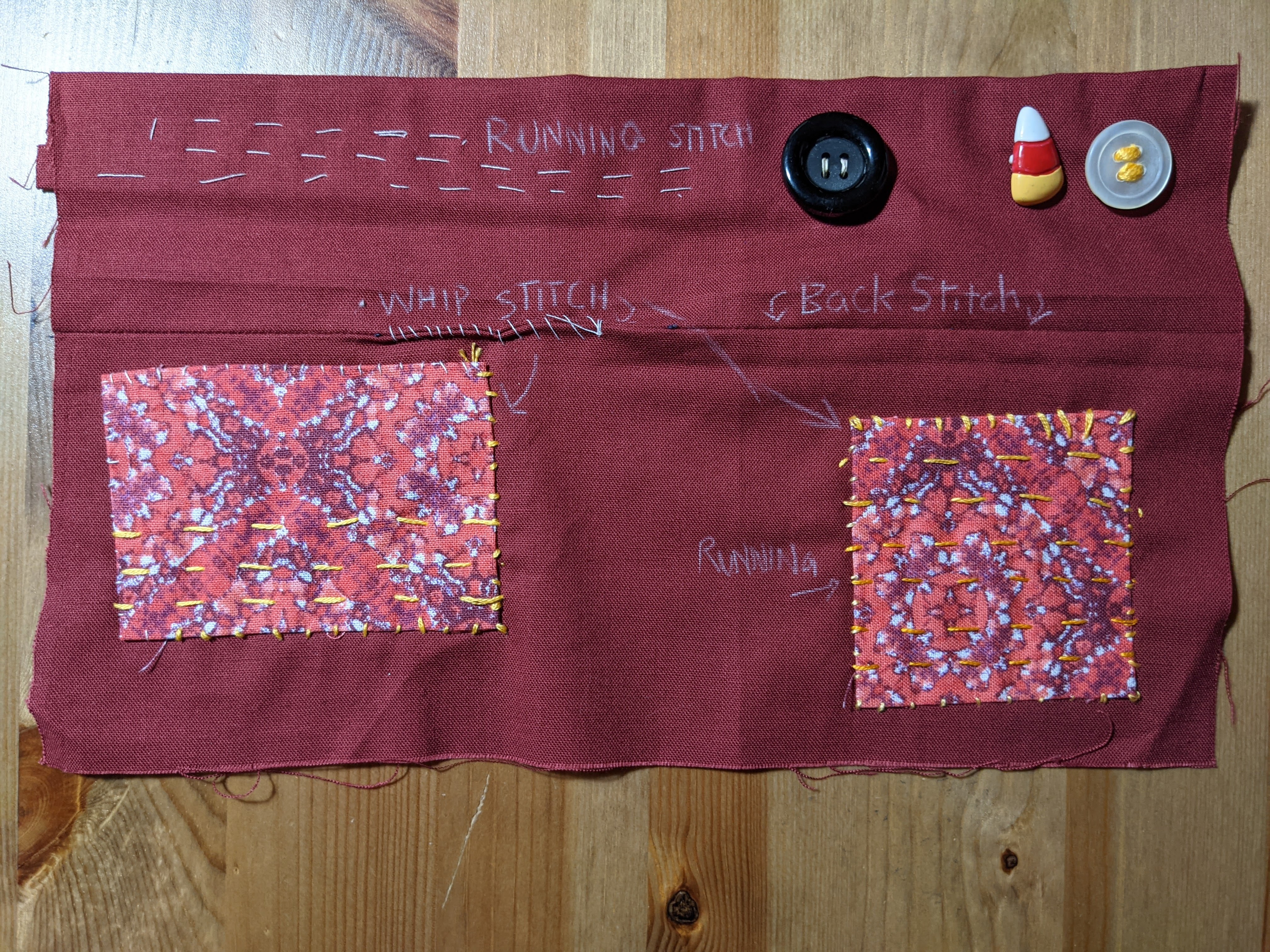

The class worked on repair projects with their own possessions and conducted research into how their items were made, packaged, and transported around the world before they wound up in a store and ultimately a home.

“We have very little connection to or awareness of how raw materials for consumer goods are sourced and processed. Much of what we own is made overseas under poor working conditions. By mapping out the lifecycle of an article of clothing, we made the impact of these global systems more tangible for students, hopefully increasing their desire to care for and extend the lives of their belongings,” commented Sanford.

Students also zeroed in on obstacles to the repair process and learned how companies like Apple intentionally discourage repair by making it difficult to access the insides of their products. “One takeaway we hoped to instill in students is that we can design products and business models differently to facilitate repair—and reuse, remanufacturing, and recycling. We just have to think about it from the beginning and consider new perspectives and opportunities in how we make, sell, use and take care of things,” said Strange.

Owen Bond (Plant Science) took the class for hands-on learning and along the way gained a much greater perspective of repair as a whole. “The biggest impact the class has had on me is how I think about consumerism. It's easy as a young person to become nihilistic when confronted with climate change caused by corporations, but in reality individual actions do matter,” reflected Bond. “Repair is connected to sustainability in that it generates very little waste. It’s also fun and allows you to be creative, while reusing old materials and saving money. On a broader scale, prioritizing repairability can even combat planned obsolescence and poor-quality products.”

As a day trip, the class visited Free Geek Twin Cities, an organization dedicated to providing access to pre-used tech products and reducing electronic waste. Students worked alongside Free Geek volunteers to disassemble electronics like computer consoles and sort parts into recyclable piles. Through this process, the class learned with their hands what design features, materials, and assembly methods make certain tech more repairable than others.

Drawn to the class initially for its focus on sustainability, Anke Wiersma (Architecture) also discovered the connective power of repair in communities and families. “By stopping pieces from reaching the landfill, I can do something that lessens the environmental impact within my community and has the potential to make life better for those that live in the future,” stated Wiersma. “When I talked to my mom about this class, she told me stories of my opa and oma teaching her how to sew a blanket stitch and repair a broken cabinet. Repair is something that everyone has a story about, even if they don’t realize it, and that is amazing.”

The class had the opportunity to meet virtually with Fixit Clinic founder Peter Mui who has helped establish clinics all over the country, including one in Hennepin County. Mui introduced students to fixit clinic processes as well as proposed legislation like Right to Repair, which would give consumers freedom to pursue independent repair options for their possessions. Students also visited the Minnesota ReUse Program to see how the University is investing in a culture of reuse. The program collects surplus furniture, supplies, and equipment from Twin Cities campuses and makes them available for purchase to the general public and for free to University departments.

Animal Science major and thrift-flipping enthusiast Bella Woolfolk enjoyed learning to fail and fitting a design course into her science-heavy schedule. "Failure is a big part of repair, and Molly and Lindsey did an awesome job of always encouraging us to try. I learned that repair isn’t just something you do when you break something, but can be a force that brings community together as a whole,” she expressed. Woolfolk is now planning to switch her major to Apparel Design next fall to fully pursue her passion.

To celebrate and culminate a semester of hard work, students in the class organized the Dare to Repair Fair on December 18 in Rapson Hall’s Courtyard. Attendees got to explore multiple booths and participate in activities including a clothing swap, a shoe cleaning station, and a tech recycling booth hosted by Free Geek Twin Cities. The fair embodied what the students learned about skill sharing and community building through collective action

If you couldn’t attend the Dare to Repair Fair but are interested in the students’ work, be sure to take a look at the digital version of the class’s zine.

To become more sustainable, Winsome Goods founder Kathryn Sieve (B.S. ’11, Apparel Design) knew she had to find a way to incorporate the leftover fabric scraps from her products into usable items. After discussing the problem with instructor Lindsey Strange (Apparel Design) it became clear that it was the perfect research project for students to tackle in the Apparel Studio I.

When Molly Sanford accepted the position as fabrication director for the College of Design’s Fabrication Shops in March 2020, her most urgent problem was a dust collector on the fritz. Two weeks and one global pandemic later, Sanford began working to reframe the crisis as an opportunity for open-hearted collaboration, creative resourcefulness, and new beginnings.

Administered by the Green Business Certification Inc. (GBCI), the Sustainable Sites Initiative (SITES) Certification provides developers with a comprehensive rating system to help them design and build more sustainable projects.