Additive manufacturing (AM), sometimes referred to as 3D-printing, offers the potential to revolutionize the manufacturing of functional/smart garments. By varying the material properties and geometries during printing, commercial AM machines can create garments that are otherwise impossible to manufacture (e.g., interlocking mesh dresses, or spatially varying elastic soles).

READ MORE

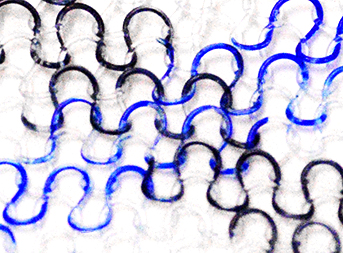

We are researching and developing a novel method for manufacturing spatially-variant functional textiles using a single multi-functional thread, leveraging the benefits of both AM techniques and traditional textiling equipment. Specifically, we are developing a method to print/extrude 1D yarn-like filament with varying (but continuous) material properties (e.g., elasticity, conductivity) -- an approach previously demonstrated for bulk materials manufacturing in soft robotic applications. We are developing methods to then feed that filament into typical textiling equipment (e.g., a Passap E6000 knitting machine) to enable the creation of a continuously knitted, single-yarn multi-functional 2D textile. This approach offers the potential to create highly specific, spatially localized functional properties in a textile/garment (without requiring the use of multiple yarns or external coatings/modifications) using industry-standard textiling equipment.

This project has three specific aims:

1. Using a Passap E6000 electronic knitting machine, we are mapping the spatial relationship between 1D linear yarn location and 2D textile (knit) location. This will enable the design of custom 2D functional textiles based on strategic varying of functional properties in a 1D filament.

2. In consultation with engineers at Stratasys, and using the spatial mapping algorithm under development, we are designing and fabricating spatially-varying multi-material filament/yarn to be knitted using the Passap E6000 machine. Parameters being studied include: yarn diameter; yarn elasticity; yarn conductivity; elasticity/conductivity gradient magnitude (e.g., ratio of maximum/minimum stiffness); and elasticity/conductivity gradient severity (e.g., rate of change of elasticity).

3. We are assessing the viability of knitting the multi-functional filament (i.e., determining the parameter envelope in which the machine successfully knits the filament); and assessing the functional properties of the knitted textile (elasticity, conductivity, durability) using traditional tensile and electrical testing techniques.

Funded by Stratasys, Ltd. and MnDRIVE