Ten years since it launched and one name change later, Toy Product Design (now Product Innovation Lab or iLab) remains one of product design's most popular courses.

The course serves as an introduction to a hands-on and cross-functional team-based product design process. The class is offered every spring and is open to everyone as an opportunity for students to get exposure to a real-world product design experience. Every detail of the curriculum is meticulously thought out and designed to enhance students’ educational experience, which made the rapid switch to remote learning an especially impressive task. “At first it truly felt like everything had to change,” said TA/Lab Instructor Krystianna Johnson. “On the surface, this course seems like one of the least online-compatible classes you could imagine as the class is not just team-based, but also requires hands-on fabrication, user-testing, in-store purchasing/research and industry collaboration.”

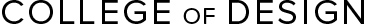

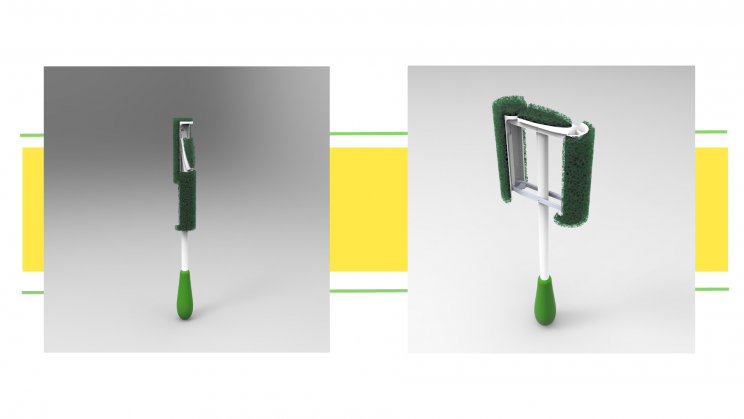

But by working together with the College of Design facilities and IT staff as well as community partners like Stratasys, who went out of their way to help the class make physical prototypes, the Product Design Program refocused and adapted to remote learning. “The biggest challenge was rethinking the course deliverables,” said Johnson. “We had to redefine the way in which students would execute the product design process.” Without campus access to prototyping resources, such as the college’s Fabrication Labs, iLab instructors scaled back the requirements for physical prototypes and instead focused on supplemental deliverables such as product branding, digital renderings, design for manufacture, online user research, storytelling, and costing.

“Despite the shift in delivery, the heart of the class stayed the same,” explained Johnson. “This class is just as much about learning how to work in interdisciplinary teams as it is about learning the product design process.” Despite transitioning to remote learning, students continued to work with their teams through this process. There were even some benefits to the new mode of teaching with students and instructors able to meet more often and the ability to invite reviewers from across the globe to provide feedback on the students’ work. The class is also designed to mimic industry product development processes and, with industry also shifting to an online model for teamwork, the class provided a realistic experience.

At the end of the semester, the students were still able to hold the annual “PLAYsentations” which is a playful, theatrical, family-friendly design showcase of the team’s final product concepts. However, with the show being virtual this year, it was renamed “STAYsentations”.

“Initially, we were all somewhat disappointed to not be able to have our signature grand finale show that the students and community are accustomed to,” said Johnson. “But presenting online allowed for a wider range of people to attend. Perhaps one of the most unique elements of this class is the community of practice teaching model that we use. Each team has two volunteer industry professionals that are lab instructors for their team and work closely with the students each week.”

Over the past 10 years, this community has grown to over 100 professionals who have been involved in different years. Having the final event online meant that dozens of former lab instructors from across the world were able to watch; one even watched the presentations from Kuwait. Many requested that the show continue to be streamed online in the future. After the virtual show, there was an outpouring of positive comments from the viewers. Composed primarily of industry professional reviewers, the audience members commended students for their outstanding presentations and work throughout the semester. One commenter added that they were extremely impressed with all of the teams, “You are all great engineers and innovators… I am proud of what you all have done!”

Johnson, a former student, TA and lab instructor, has been involved with the Product Design Program and iLab course for nine years. She’s not alone in her dedication to the class and program. Many of the industry lab instructors for product design courses are former students while others are members of the design and engineering industries.

“It has been so rewarding to stay involved with this community as an instructor and teaching assistant and to be a part of the behind the scenes magic that goes into designing the experience,” said Johnson. “Being involved with this class and the product design program has been one of my most enriching and enjoyable experiences at the University. The teaching model put in place by Program Director Barry Kudrowitz and the philosophy of a community of practice fosters a very unique teaching and learning environment which has been cultivated through ten years of product design classes. It truly is one of the most unique course experiences, and programs, that I have been involved in. It has been a pleasure and privilege to be an instructor for so many students over the years and to witness the teamwork, dedication, and incredible product development that this course elicits,” she concluded.

Now in its seventh year at the University of Minnesota, the College of Design’s Toy Product Design class is known for its playful atmosphere and rigorous pace.

If there is one thing students in Toy Product Design know, it’s how to play hard and work even harder. All semester long, they’ve been creating the next big thing in toy design and on May 3rd all of that hard work will pay off when they present their final products at PLAYsentations.

Driven by the acute need for N95 masks in hospitals, faculty from the University of Minnesota’s College of Design, College of Science of Engineering, and medical school worked together to create two face mask designs that could be assembled using available materials.